-

Materials

-

Applications

Petrochemical Energy -

Customizable Machining

Reverse engineering from drawings and samples.

-

Product Description

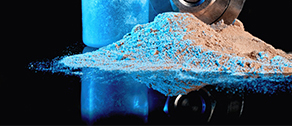

JFM specializes in custom porous ceramic parts, offering tailored solutions through reverse engineering from design drawings or physical samples. Our products, including diatomaceous earth drying plates and zirconia-bonded porous ceramics, are widely used in drying, filtration, and catalysis applications.

-

Product Properties

- High Pressure Resistance

- High Temperature Resistance

- Good Mechanical Strength

- Corrosion Resistance

- Long Lifespan

- Controllable Fine Pore Structure and Porosity